Learn More Today

If you’d like to learn more about how Cutting Dynamics can provide aerospace solutions to your company, reach out to us below or call us at 888-235-2737.

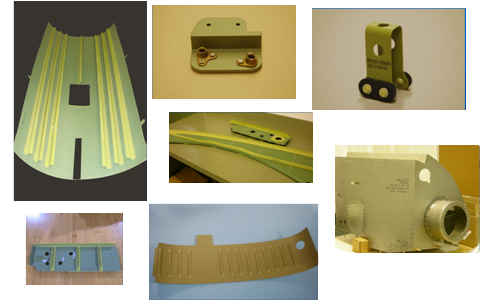

Aircraft Assemblies

Since 1985, Cutting Dynamics has engineered and manufactured complex assemblies for clients in a variety of industries.

We specialize in hydroformed aluminum and hot-formed titanium components, aircraft assemblies, aerospace assemblies, composites, and kitting for the aircraft industry.

And as our technological capabilities grow – we have one of the world’s most advanced systems for processing continuous and chopped fiber thermoplastic composites – we are able to better service our strategic partners. Thanks to our growing complex assemblies, team, and facility, we will be there every step of the way with your best interests in mind.

Read on to discover everything Cutting Dynamics can supply for your needs for complex assemblies, such as aircraft assemblies, and be sure to reach out to us with any questions.

Choose Cutting Dynamics for Complex Assemblies

- Hydroforming lightweight metal components – In-house tooling design, repair, and manufacturing capabilities enable us to respond quickly to customer requirements. We routinely handle complicated parts including curved piece and smaller-run productions. Our state-of-the-art tri-from press and new robots enable us to fabricate to the tightest tolerances

- Thermoplastic composite manufacturing – We offer capabilities to provide components like arm rests, table slides, end bays, spanner bars, wind spars, flooring, seat backs, seat pans, and more

- We have expertise in continuous fiber products / chopped fiber products and stretch broken fiber products

- Assembly/kitting – We have a structural team experienced in aircraft assemblies, and our barcoding and electronic record-keeping system that makes our kitting department as efficient as possible in managing inventory for large-scale aircraft component kits

- Hot form titanium – From tool design and manufacturing to 5-axis robotic trimming, our hot forming titanium department is able to supply a wide range of capabilities to ensure you receive the key components you need

For our hot forming titanium capabilities, we are able to work with essential materials like titanium, Inconel, and certain grades of stainless steel. When it comes to complex assemblies, such as titanium assemblies, hot forming is ideal for components that need to withstand heat such as:

- Jet engines

- Firewalls

- Missiles

- Other aviation parts

One of the major reasons titanium assemblies are prized is because titanium is known for its high strength, with it being 30% stronger than steel and 100% stronger than aluminum. Additionally, the material has a weight that is 50% lighter than steel, making it particularly well suited when it comes to complex assemblies in the aerospace field.

Our Work for Aerospace Assemblies and Aircraft Assemblies

From large to small applications, Cutting Dynamics can fulfill all of your needs for complex assemblies. And by working with a variety of materials, including aircraft-grade aluminum, #4130 steel, stainless steel, titanium, and thermoplastic carbon fiber, we can truly adapt ourselves to any type of client.

Some of the clients we have had the good fortune of working with over the years include:

- Bell

- Gulfstream

- Spirit AeroSystems

- Cessna

- Sikorsky

- B/E Aerospace

- Airbus

- Parker

We provide all the resources needed to manufacture your components, while cutting your turnaround time. This way we can guarantee that our aerospace assemblies meet your needs. If you’re looking to acquire aerospace assemblies or aircraft assemblies from a trusted industry leader, choose Cutting Dynamics.

Learn More About Our Complex Assemblies Today

No matter the application, we look forward to supplying the complex assemblies and components your company needs.

To learn more, be sure to contact Cutting Dynamics today.